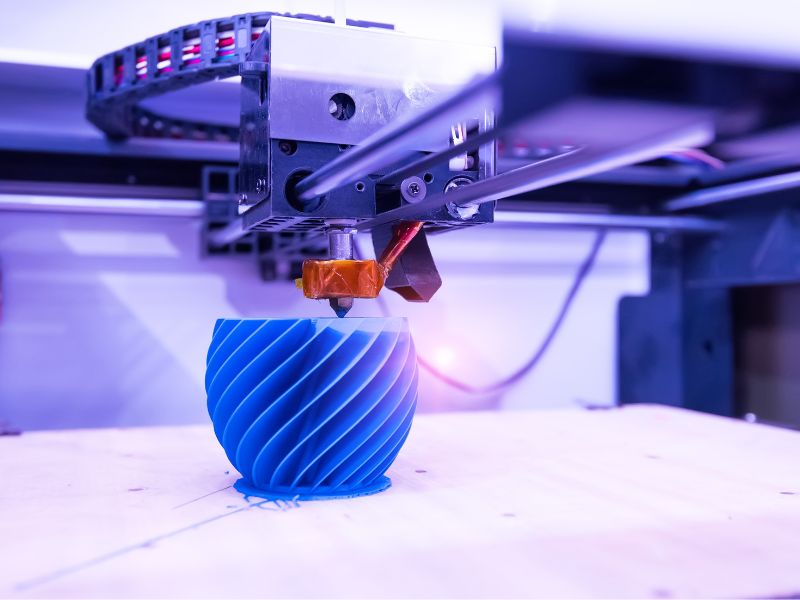

In recent years, the advent of 3D printing has ignited a technological revolution, changing the manufacturing landscape in many industries. This groundbreaking technology allows us to produce complex objects layer by layer, and opens new horizons for innovation and efficiency. Moral Technologies recognizes the profound impact 3D printing has on our work.

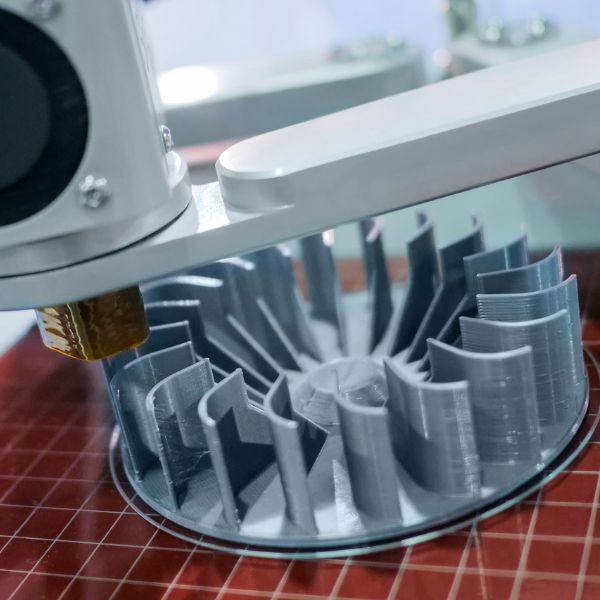

Traditional manufacturing methods often impose limitations on design due to limitations in tooling and assembly processes. However, 3D printing empowers engineers and designers by offering unprecedented design freedom. Complex geometries, complex internal structures and customized components are now within reach, enabling the creation of optimal parts that were once unattainable. This flexibility enables improved performance, reduced weight and improved functionality in a wide variety of applications, from aerospace to military industries to model manufacturing and medical devices.

Prototyping plays a crucial role in product development, allowing engineers to evaluate designs, assess functionality, and identify potential improvements. In the past, prototyping was a time-consuming and expensive process. 3D printing has revolutionized this aspect of engineering. With capabilities to rapidly produce prototypes directly from digital designs, 3D printing dramatically shortens development cycles while also simplifying design processes. This accelerated timeline translates to faster innovation and shorter time to market for new products and technologies. time is money!

In an era where customization is highly valued, 3D printing allows the creation of products adapted to personal needs. By leveraging digital designs and parametric modeling, manufacturers can produce customizable products at scale. From consumer products such as footwear and glasses to medical implants and prostheses, 3D printing empowers us to create customized solutions that enhance the user experience and improve the quality of life. This shift from mass production to mass customization represents a paradigm shift in the way we make products.

The engineering department of Moral Technologies Ltd. uses all the possibilities offered by 3D printing for the research and production of spare parts, tools on demand, models of missiles, airplane models and more. Working with 3D printing can significantly reduce the weight and volume of the objects, which makes the The tasks are more practical and economical than traditional production.

3D printing heralds a new era of manufacturing, with far-reaching implications for industries around the world. From design customization and rapid prototyping to customization and supply chain optimization, the benefits are deep and varied. Moral Technologies Ltd. saw the transformative power of 3D printing and its potential to revolutionize the world of manufacturing and industry. The adoption of this technology is essential for the industry to unlock innovation, drive efficiency and create a sustainable future. Moral Technologies is a leader in the field of 3D printing. Anything you want. There is no limit to what can be produced with this amazing technology. You will imagine, and we will produce.

For more details about 3D modeling and printing, write to us or call +972-49552127